Why Mandrel Foam Trailers Beat Panel Foam Construction

When thinking of refrigerated trailers, also known as “reefers”, they may be described as a big white box on wheels. To many, these trailers “all look the same”, but inside are products like cheese, meat, ice cream or blood plasma.

The construction of the trailers is an exterior aluminum panel riveted to an aluminum side post, polyurethane foam sandwiched between the exterior and an FRP or thermal plastic interior lining or extruded aluminum floorboard. While they all look similar, they are, in fact, very different resulting in a difference in thermal efficiency.

Thermal efficiency is important because a reefer keeps things cold in the heat of summer and protects from freezing in the cold of winter. “Panel Foam” construction is less expensive and generally results in a heavier trailer. While a “Panel Foam” trailer has the same foam as a “Mandrel Foam” trailer, the floor, sidewalls, and roof are foamed separately and joined, or butted, together which can result in small gaps where air exchange can happen. The “Mandrel Foam” trailer is assembled and liquid foam is injected, expands and fills all the areas where the interior, exterior, roof, side and floor meet. There are no gaps like a panel foam trailer, resulting in superior thermal efficiency.

Thermal efficiency is important because a reefer keeps things cold in the heat of summer and protects from freezing in the cold of winter. “Panel Foam” construction is less expensive and generally results in a heavier trailer. While a “Panel Foam” trailer has the same foam as a “Mandrel Foam” trailer, the floor, sidewalls, and roof are foamed separately and joined, or butted, together which can result in small gaps where air exchange can happen. The “Mandrel Foam” trailer is assembled and liquid foam is injected, expands and fills all the areas where the interior, exterior, roof, side and floor meet. There are no gaps like a panel foam trailer, resulting in superior thermal efficiency.

Panel Foam

Many manufacturers use the panel foam method when building reefers. Great Dane, Wabash, Vanguard, Hyundai, and others utilize it during construction. As described above, the walls are built and foamed before joining them to the floor and roof. The wearband on the side wall is commonly attached with a mechanical fastener to a wood block that is attached to an aluminum side post. We call this a direct heat/cold short, even though the wood is a little bit of an insulator. It’s why you may see ice buildup on the exterior of a panel foamed trailer in the lower 16” to 24” specifically at the side posts. The cold is cooling the post enough that the moisture is freezing to the panel on the exterior. During a humid summer day instead of ice, it will appear as though the trailer is sweating at the side posts.

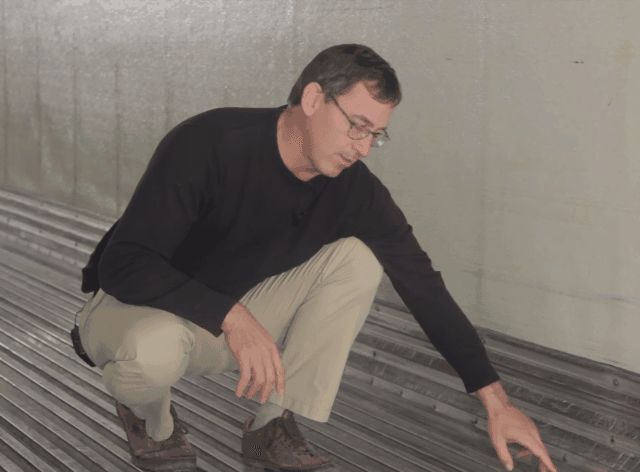

Exposed Fastener

The mechanical fasteners on panel foam trailers are exposed to damage even though they are placed in the recess of the corrugated aluminum wearband. Pallets and the steel wheels of forklifts can shear the screw heads and fasteners that hold the wearband in place. Each sheared rivet or screw head results in an entry point for moisture. Since reefer trailers are used to keep the load cold, there is a lot of opportunity for moisture within the trailer to then penetrate the foam wall through the exposed fastener hole(s). The moisture gets trapped in the foam and increases the weight of the trailer. It can also damage the foam cells as it expands due to freezing interior or exterior temperatures. The degradation of foam results in a less thermal efficient trailer.

The mechanical fasteners on panel foam trailers are exposed to damage even though they are placed in the recess of the corrugated aluminum wearband. Pallets and the steel wheels of forklifts can shear the screw heads and fasteners that hold the wearband in place. Each sheared rivet or screw head results in an entry point for moisture. Since reefer trailers are used to keep the load cold, there is a lot of opportunity for moisture within the trailer to then penetrate the foam wall through the exposed fastener hole(s). The moisture gets trapped in the foam and increases the weight of the trailer. It can also damage the foam cells as it expands due to freezing interior or exterior temperatures. The degradation of foam results in a less thermal efficient trailer.

The benefit of the mandrel foam method and not having exposed fasteners is pretty clear. Since there are no places where rivets can be sheared off, moisture does not have the same accessibility to get through into the foam. Additionally, panel foam trailers rely on the fastener that attaches the wearband to the side post and the rivets that attach the floor to the wearband.

The benefit of the mandrel foam method and not having exposed fasteners is pretty clear. Since there are no places where rivets can be sheared off, moisture does not have the same accessibility to get through into the foam. Additionally, panel foam trailers rely on the fastener that attaches the wearband to the side post and the rivets that attach the floor to the wearband.

Bottom Line

A Mandrel Foam trailer without interior screws or rivets is less likely to allow moisture into the sidewall. There is less probability of air exchange too, resulting in a more thermal efficient trailer. Look closely when deciding what reefer to purchase. We are sure you can see the difference.